Inspections of Wind Turbine Gearboxes

1. Background

|

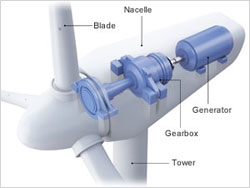

Wind power generation is more economical than nuclear and thermal power generation, and it is rapidly growing as a source of clean energy. Natural wind is available free of charge, so the main costs for wind power generation construction and maintenance. It is said that wind turbines have a lifespan of 20 years, Just like thermal power plants, wind turbines require periodic inspections and repairs in order to achieve this 20 year lifespan. Throughout this operating period, the gearbox, blades and all other parts of each wind turbine are thoroughly inspected,. When inspecting wind turbine gearboxes, Remote Visual Inspection is the most proven and effective method.

|

2. Challenges and Solutions

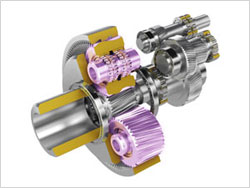

When transmitting the rotating force of a wind turbine with a diameter of 90 to 200 m to a generator, the gearbox must operate under severe strain and naturally requires inspection and maintenance.

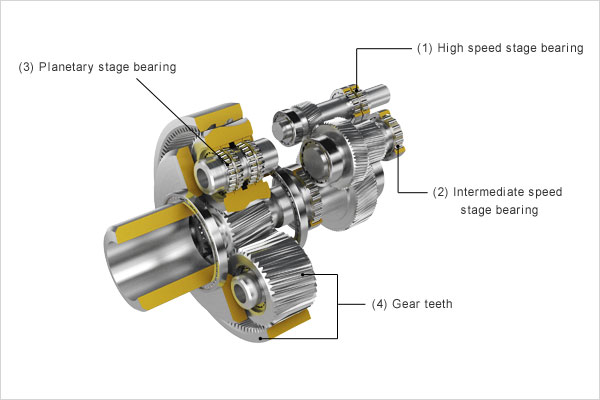

(1) High speed stage bearings (HSS-B)

• Challenge

|

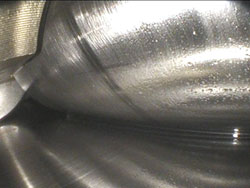

The high speed shaft is supported by the high speed stage bearings located on the front and back sides of the shaft, which makes 1500 to 1800 revolutions per minute during power generation.

If there is any misalignment between the high speed shaft and the connected generator, unexpected minor vibrations will occur and may cause damage to the bearings. The high speed stage bearings may also be damaged by foreign matter, air or moisture contained in the lubrication oil. What is worse, due to the high speed rotation of the high speed stage bearings, once a bearing roller has broken, it may lead to breakage of other parts of the gear box, resulting in a need to replace the entire gearbox. |

• Solution

|

In most gearboxes, high speed stage bearings can be easily accessed by using the IPLEX videoscope through a hatch (opening) located above it. The IPLEX videoscope can be inserted into a gap at a bearing roller to inspect and record minor flaws on the roller surface, the inner race and the outer race. If you find that flaws have grown larger than they were in the previous inspection, you can replace the high speed shaft and the high speed stage bearings on the wind turbine before the damage spreads to other areas. This means that you can do the maintenance without lowering the gearbox onto the ground using a crane or other costly devices and causing power loss during the repair.

|

(2) Intermediate speed stage bearings (ISS-B)

• Challenge

|

The intermediate shaft is located between the high and low speed shafts and supported by the intermediate speed stage bearings located on the front and rear sides of the shaft. These bearings may be damaged by the same factors as those for the high speed stage bearing mentioned above.

|

• Solution

|

The inspection methods of the high speed stage bearings are effective for the intermediate speed stage bearings too. However, this inspection may be more difficult, because it is necessary to insert an endoscope beyond the high speed shaft. To assure smooth entry of the endoscope, it can be inserted through a semi-flex guide tube made of resin and aluminum highly resistant to oil.

|

(3) Planetary stage bearings

• Challenge

|

The wind force acting on the turbine varies depending on the influences of land features, the height from the ground and turbulence caused by changes in the weather. While this variable force imposes a heavy burden on the gearbox, the planetary gear and the planetary stage bearings serve to absorb the varying wind stress. Though the rotating speed is only 20 to 30 revolutions per minute, the planetary gear is subject to significant stress applied by turbulent airflow. For this reason, visual inspections with endoscopes are required for not only planetary stage bearings but also the planetary gear. |

• Solution

|

Planetary gears have complicated structures and are generally difficult to access, but the inspection efficiency can be dramatically improved by inserting the IPLEX videoscope through the Olympus' shape-memory urethane guide tube customized to meet individual inspection purposes. In addition, the IPLEX videoscope of 6.2 mm outer diameter with a built-in channel has a capability to remove the lubrication oil adhered onto the planetary stage bearings, the planetary gear or the scope tip by injecting compressed air from the scope tip, which enables to conduct inspections in clear vision.

|

(4) Gear teeth

• Challenge

Gears work to absorb wind stresses putting on turbine blades. The continuous wind force results in aged deterioration of gears. Although whole condition of gearbox is constantly monitored by vibration analyzers, visual inspection with an endoscope is essential in order to ascertain location and level of damages on gearbox parts including gear teeth.

• Solution

|

The gear teeth for each shaft are also subject to visual inspections as well as the bearings. Especially inspections of the low speed shaft gear, the planetary gear and the ring gear require endoscopes. When inspecting these complex gears, you need to take care to keep the scope tip free from oil. The Olympus' guide tube used for bearing inspections can also be used in this inspection. Most gear teeth are longer than 10 cm, but the flaws to be detected are generally very small. Near focal optical adaptors of the IPLEX videoscopes greatly aid the inspection of gear teeth.

|

(5) Turbine blades

• Challenge

In general, quality inspections of the turbine blades longer than 40 m are held during production. For inspecting the joint on the trailing edge of a blade, you can go halfway into the blade, but cannot go further because the space becomes smaller toward the blade tip. In addition, the turbine blades under operation also need to be inspected as they are exposed in harsh environment all year long. If the drain hole on the blade tip is clogged, internal water may suddenly vaporize in the case of a lightning strike and may break the blade from the inside. In winter, internal water of the drain hole may freeze and expand to break the blade.

• Solution

The small and lightweight videoscope in the IPLEX series allows you to easily bring it halfway into the blade and conduct visual inspection of the blade tip.

3. Key Benefits with Olympus

(1) Portability for higher work efficiency of inspectors

|

When inspecting a large-sized wind turbine taller than 70 m, inspectors are required to climb a long ladder carrying inspection tools. Olympus offers various videoscopes combining excellent image quality and portability.

The IPLEX models with the unique PulsarPic technology reveal details inside the gearbox with bright and sharp images, while finely adjusting the light volume to reduce reflection that often occurs during the observation of metal parts. The TrueFeel articulation technology allows an operator to precisely control the scope articulation within the gearbox, preventing the scope tip from touching the lubricant oil on the gears. |

|

The palm-sized, handheld model of the IPLEX series can be comfortably carry to even hard-to-reach sites like the top of the wind turbine towers.

|

(2) Excellent optical performance for clear observation of bearing surfaces

|

Bearings are the most commonly inspected of all the parts in a wind turbine gearbox and suitable endoscopes vary depending on the designs and locations of bearings. The IPLEX videoscopes with diameters of φ4 mm to φ8.5 mm can switch magnification and direction of view for optimal observation by changing the optical adapters at the scope tip. To utilize 120° field of view near focus adaptor makes it possible to observe bearing surfaces in a large field of view by inserting the endoscope into a small gap at a bearing roller.

|

(3) Specialized tools to facilitate clear observation of large gear parts

The entire gearbox is lubricated with oil, so a lot of oil remains on the gears and bearings even after the gearbox is stopped. When inspecting these parts with an endoscope, you need to keep the lens free from oil. The IPLEX videoscopes of 6.2 mm outer diameter with a built-in channel has a capability to mount a slim air tube and can blow oil off the gear and bearing surfaces by injecting air from the air tube. Even if oil adheres to the tip of the scope lens, it can be removed by air injection and eliminates the need to frequently wipe oil off the scope tip.

In addition, there are some cases that a large amount of light is required for inspections of gears. Olympus' custom-made LED guide tube, which is bendable as an operator wants, can be smoothly inserted into the gearboxes through an access port and deliver auxiliary LED illumination to the intended parts.

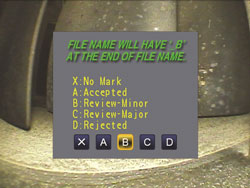

(4) The Inspection Assist Software for reliable recording of inspections

|

In a gearbox inspection with an endoscope, it is common to record 100 to 400 images. The inspected images of bearings supporting the various shafts will be very similar each other, so you will have to make a big effort to correctly classify the similar images by inspected location during and after inspections.

In such a situation, our Inspection Assist Software is the solution. By conducting an inspection as the software guides, you can classify inspection images with diagnosis into folders and add comments to the images. After the inspection, you can quickly make a report containing more than 50 images by utilizing the software on your own customized report format. |

(5) Equipment for inspections other than visual inspections

Olympus also provides ultrasonic flaw detectors and x-ray analyzers to support inspections of wind power facilities.

The ultrasonic flaw detectors allow you to detect damages inside turbine blades. In addition, with our battery-powered X-ray analyzer, you can immediately clarify the type, size and amount of metal included in the lubrication oil inside gearboxes at inspection sites.

Products used for this application

InHelp

InHelp is inspection data management and reporting software for Olympus Industrial videoscopes that streamlines all aspects of on-site inspections. It is greatly improves your work efficiency by organizing stored images and generating detailed inspection reports.

IPLEX G Lite

The IPLEX G Lite industrial videoscope packs powerful imaging capabilities into a small, rugged body. Lightweight and able to go almost anywhere, users working in challenging applications have a remote visual inspection tool with the image quality and ease of use to get the job done.

IPLEX NX

The IPLEX NX videoscope combines our highest-quality images with an intuitive user interface, ergonomic design, and durability for efficient inspection in nearly any environment. Its clear, bright images and powerful measurement features are built to exceed expectations.