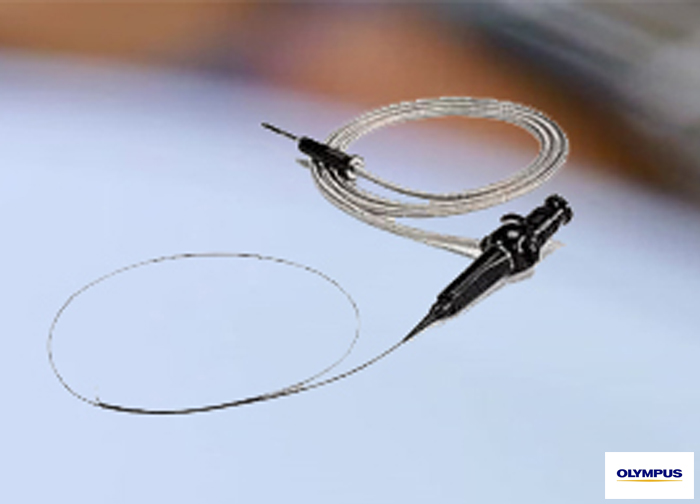

Rev-volutionizing Engine Inspections with IPLEX™ GX/GT Videoscopes

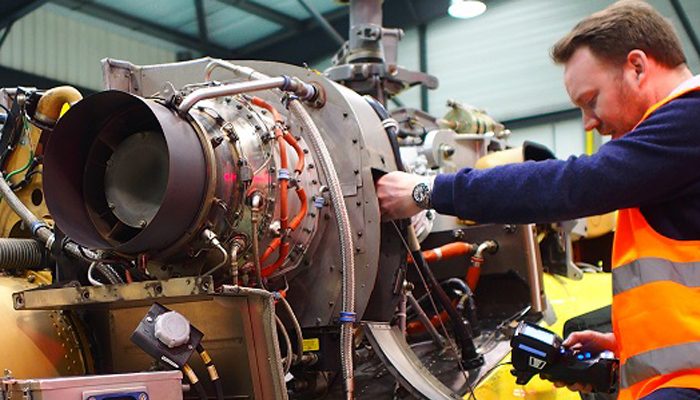

When people think about industrial videoscope inspections, they typically think of large machinery and components, such as aircraft engines or wind turbines. But did you know videoscopes also play a valuable role in looking at the inside of a car engine?

Soon after we launched our new IPLEX™ GX/GT videoscopes, the research and development (R&D) team of a major automotive OEM in Germany used our new scope to look inside their new engines after overnight test runs.

Today’s blog will share how our videoscopes helped with their inspection.

Checking for Car Engine Defects with a Videoscope

Testing an engine in tough conditions can cause many different small defects inside the engine. Despite being small, these defects are often an important early warning sign that something’s gone awry in the manufacturing or setup of the engine. Videoscopes are a quick and easy way to look inside, especially when you don’t want to disassemble the engine.

Generate Revenue with Versatile Videoscopes

Engine inspections are an excellent example of how versatile videoscopes, such as Olympus’ IPLEX GX/GT series, are an asset in the automotive industry. And not just in R&D—manufacturing, quality control (QC), and in-service inspections can all benefit from the high light intensity and easy maneuverability the IPLEX has to offer.

These benefits can help you streamline inspections and ensure durable, reliable engines (and ultimately help to generate rev-venue).

To learn more about using our versatile videoscopes for engine inspections, read this application note next, IPLEX GX/GT—Fast and Reliable Inspections for Automotive OEMs.

You can also discover more IPLEX GX/GT videoscope benefits here.

Related Content

IPLEX GX/GT—Fast and Reliable Inspections for Automotive OEMs

IPLEX GX/GT Manufacturing Inspection Video

IPLEX GX/GT Industrial Videoscope Brochure